Table of Contents

Manufacturing businesses across the globe face numerous challenges in optimizing their production processes, managing inventory, and ensuring efficient workflows. To address these complexities, Odoo, a powerful and versatile open-source business management software, offers a comprehensive Manufacturing module. In this article, we will explore the features, benefits, implementation, and real-life use cases of the Odoo Manufacturing module, providing you with valuable insights into how it can transform your manufacturing operations.

Features and Benefits of the Odoo Manufacturing Module

The Odoo Manufacturing module is a feature-rich solution designed to streamline and automate manufacturing processes. It caters to diverse industries, including discrete manufacturing, process manufacturing, and make-to-order or make-to-stock environments. By leveraging this module, businesses can achieve increased productivity, enhanced quality control, efficient resource utilization, and improved visibility into their production operations.

Key Functionalities of Odoo Manufacturing Module

Product and Bill of Materials Management

At the core of the Odoo Manufacturing module lies the efficient management of products and bills of materials (BOMs). Users can easily define and organize their product catalog, create hierarchical BOM structures, and track raw material consumption. The module also supports versioning of BOMs, enabling businesses to maintain accurate records of their production recipes.

Work Order Management

With Odoo Manufacturing, you can effortlessly create and manage work orders to execute production tasks. The module offers comprehensive work order views, enabling supervisors to track the progress of each order, assign resources, and monitor timelines. This feature ensures optimal utilization of labor, machines, and tools while maintaining visibility throughout the production cycle.

Production Planning and Scheduling

Efficient production planning and scheduling are crucial for meeting customer demands and optimizing resource allocation. Odoo Manufacturing provides intuitive planning tools that allow businesses to create production plans, define routings, and schedule operations. The module considers various factors such as lead times, machine availability, and material availability to generate realistic production schedules.

Quality Control and Traceability

Ensuring product quality and maintaining traceability are paramount in manufacturing. The Odoo Manufacturing module incorporates robust quality control features that facilitate the definition of quality control points, inspection criteria, and tests. It also enables the tracking of products throughout the production process, providing end-to-end traceability for compliance and quality assurance purposes.

Inventory Management and Warehouse Operations

Effective inventory management is vital for manufacturing businesses to avoid stockouts and overstocking. Odoo Manufacturing offers comprehensive inventory management capabilities, allowing businesses to track stock levels, manage replenishment, and automate procurement based on production requirements. The module integrates seamlessly with the Odoo Inventory module, providing real-time visibility into stock movements and optimizing warehouse operations.

Reporting and Analytics

To make informed business decisions and monitor production performance, Odoo Manufacturing provides a range of reporting and analytics tools. Users can generate customizable reports on key metrics such as production output, resource utilization, material consumption, and quality control. The module also offers visual dashboards and charts, enabling stakeholders to gain valuable insights into their manufacturing operations.

Implementation and Customization of Odoo Manufacturing Module

Implementing the Odoo Manufacturing module requires careful planning and configuration to align it with specific business requirements. The following steps outline the process:

Setting up Manufacturing Operations

Start by configuring the basic manufacturing settings in Odoo, such as defining the manufacturing company, selecting the manufacturing journal, and setting up production teams and shifts.

Configuring Work Centers and Routings

Next, create work centers to represent the various stages of workstations involved in the manufacturing process. Assign appropriate resources, define capacities, and establish routing sequences to ensure smooth production flow.

Defining Bill of Materials

Create a bill of materials (BOMs) for each product, specifying the raw materials, sub-assemblies, and labor required for production. Include accurate quantities, associated costs, and any special instructions or notes.

Creating and Managing Work Orders

Generate work orders based on sales orders, demand forecasts, or internal requirements. Assign work orders to specific work centers, schedule operations, and track progress throughout the production cycle.

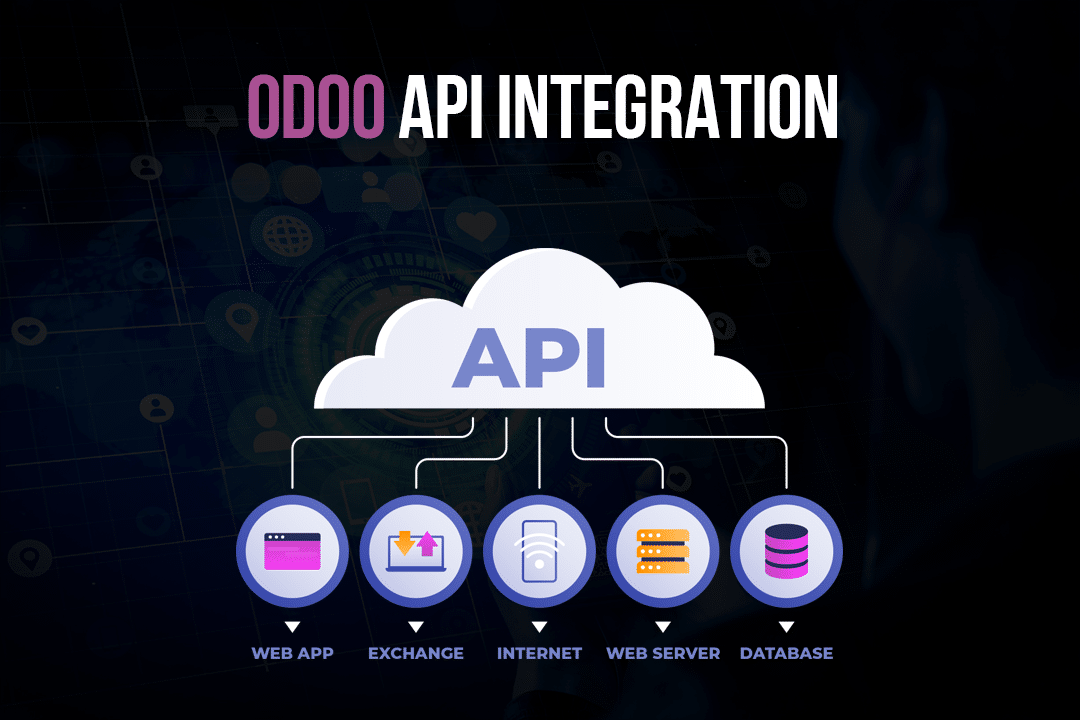

Integrating with Other Odoo Modules

Leverage the seamless integration capabilities of Odoo to connect the Manufacturing module with other modules such as Sales, Purchase, Inventory, and Accounting. This integration ensures smooth data flow, eliminates duplication and enhances cross-functional collaboration.

Customizing the Manufacturing Module

Odoo offers extensive customization options to tailor the Manufacturing module to unique business needs. Customize fields, forms, and workflows, and create additional reports and dashboards as required.

Real-Life Use Cases of Odoo Manufacturing Module

The Odoo Manufacturing module caters to a wide range of industries and manufacturing environments. Here are some real-life use cases:

Small and Medium-Sized Enterprises

Small and medium-sized enterprises (SMEs) can benefit greatly from the Odoo Manufacturing module. It offers an affordable yet powerful solution to streamline production processes, automate workflows, and improve overall operational efficiency.

Discrete Manufacturing

Manufacturers producing distinct, individual units or products can leverage the Odoo Manufacturing module to manage their production lines efficiently. Whether it’s assembling electronic devices, fabricating machinery, or crafting customized furniture, the module provides the necessary tools for precise control and optimization.

Process Manufacturing

For businesses involved in process manufacturing, such as food and beverage, chemical, or pharmaceutical industries, the Odoo Manufacturing module offers specific features for managing complex production processes. From recipe management to batch tracking, it ensures compliance, quality control, and efficient resource utilization.

Make-to-Order and Make-to-Stock Environments

Odoo Manufacturing supports both make-to-order (MTO) and make-to-stock (MTS) manufacturing environments. Businesses can configure the module to cater to their specific production strategies, whether it involves producing goods based on customer orders or building stock in anticipation of demand.

Multi-Location and Multi-Company Operations

Companies with multiple manufacturing facilities or operating in different locations can efficiently manage their operations with the Odoo Manufacturing module. It provides centralized control, visibility, and coordination across various sites or subsidiaries, ensuring smooth interactions and effective resource allocation.

Challenges and Limitations of the Odoo Manufacturing Module

While the Odoo Manufacturing module offers robust features and benefits, it’s important to be aware of certain challenges and limitations. These include:

The Complexity of Implementation: Implementing the Odoo Manufacturing module may require expertise in configuring the system to align with specific manufacturing processes and business requirements. Adequate planning, training, and support are crucial for a successful implementation.

Customization Complexity: While Odoo provides extensive customization options, complex customization requirements may require technical expertise or the involvement of Odoo partners or developers.

Scalability: While the Odoo Manufacturing module is suitable for small to medium-sized enterprises, scaling up to larger operations with complex manufacturing processes and high transaction volumes may require additional customization and performance optimization.

Integration with External Systems: Integrating Odoo Manufacturing with third-party systems or legacy software can be challenging and may require custom development or utilizing Odoo’s API capabilities.

Localization and Industry-Specific Requirements: Adapting the Odoo Manufacturing module to specific local regulations, compliance standards, or industry-specific requirements may require additional customization or configuration.

Conclusion

The Odoo Manufacturing module serves as a comprehensive solution for businesses aiming to streamline their production processes, enhance resource utilization, and gain better visibility into their manufacturing operations. With features such as product and BOM management, work order tracking, production planning, and quality control, Odoo Manufacturing offers the necessary tools for efficient and effective manufacturing management. One Stop Odoo helps you implement and customize the module to fit their unique requirements, businesses can achieve increased productivity, improved quality control, and enhanced overall operational efficiency.